GEOLOGY HAPPENINGS January 2020 |

||||||||||

| Harvesting from an Ancient Sea: Potash Production by Allyson Mathis |

||||||||||

An unusual suite of rocks is present underneath the canyon country surrounding Moab: salt deposits along with other evaporite minerals such as potash (potassium chloride that occurs as the mineral sylvite). Evaporite minerals are deposited from hypersaline seas known to geologists as restricted basins. Approximately 310 million years ago, a restricted basin existed in what is now southeastern Utah. Rivers cascading down from the Ancestral Rocky Mountains to the northeast carried dissolved salts and other minerals into the basin, which was partially, or even sometimes completely, cut off from the open ocean. Because circulation with normal ocean water did not exist, concentrations of sodium, potassium, and other ions in the water progressively increased with evaporation, ultimately reaching concentrations where first salt (halite), and then potash precipitated to form vast layers of salts on the sea floor. (The December 2019 Geology Happenings article describes the geology of the potash deposits in more detail. See www.moabhappenings.com/Geology

In the early 1960s, the Texas Gulf Sulphur Company began to develop the reserves. A 2,789-foot deep shaft was sunk to reach the uppermost sylvinite layer, and a processing mill was built. The state constructed a new road (Highway 279) to the potash plant, and the Denver and Rio Grande Railroad built a spur to connect the new mine to markets.

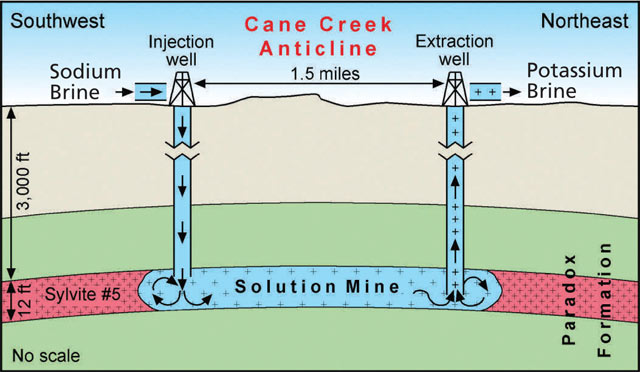

during the summer in order to maximize evaporation/production when the temperatures are the greatest. The harvested salt-potash mixture is sent to the mill in slurry pipes where potash is separated from salt through a process called froth flotation. During processing, compounds are added to the mixture that causes the potash to “float.” The potash is then dried, and then shipped to the warehouse. Potash produced at the Cane Creek mine is at least 95% pure, with the majority of the balance consisting of salt and moisture. Their annual potash production is between 80,000 and 120,000 tons, with wind, rain, and other weather conditions impacting production. Intrepid Potash has operated the Cane Creek mine since 2000. Intrepid increased production by using horizontal drilling to follow the sylvinite layers and by mining a second (and deeper) sylvinite layer (Potash 9), in addition to original ore layer (Potash 5). Intrepid Potash estimates that they have reserves that should last between 70 and 100 years at the Cane Creek mine.

Geology plays an oversized role in nearly every aspect of canyon country. The influence of geology is sometimes self-evident, such as with the scenery. But sometimes it is not as obvious. For Intrepid potash, the key factors are the combination of the 310-million year old restricted basin where sylvite was precipitated after extreme evaporation, and the slight upwarp at the Cane Creek anticline that brought this valuable commodity closer to the surface where the salts from that ancient sea are now harvested.

|

||||||||||

|

||||||||||